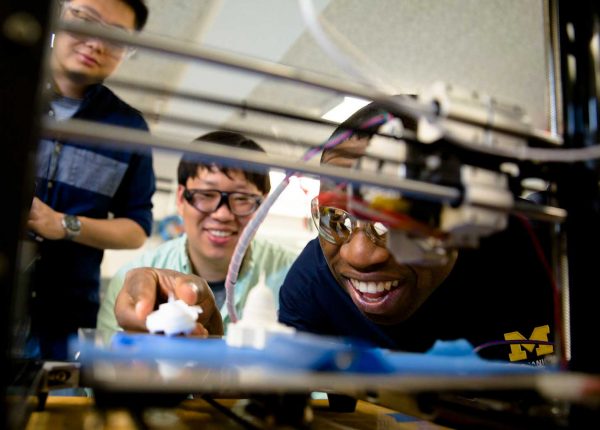

Molong Duon and Deokkyun Yoon, both mechanical engineering PhD students, and Chinedum Okwudire, associate professor in mechanical engineering, examine the effectiveness of their new, faster 3-D printing algorithm. (Evan Dougherty, Michigan Engineering)

Because of the vibrations caused by their operation, today’s 3-D printers operate very slowly, often taking hours to complete a small object. A new software algorithm developed at U-M allows printers to deliver high-quality results at speeds up to two times faster than those in common use, with no added hardware costs.

According to Chinedum Okwudire, associate professor of mechanical engineering who directs U-M’s Smart and Sustainable Automation Research Lab, the program anticipates when the printer may vibrate excessively and adjusts its motions accordingly. “Eventually, one of the places we would want to see the algorithm applied is in the firmware—the software that runs on the printer itself. That way, it will be integrated with the printers, regardless of the size,” he said.

Okwudire said his software can also be used on a variety of industrial-grade machines that suffer from similar limitations due to vibrations.